- 1

- 2

Complete equipment for continuous fiber reinforced thermoplastic composites

(jointly developed with Beijing University of Chemical Technology) - unidirectional prepreg production line

Unidirectional prepreg belt production line

① Basic resins: PP, PE, pet, PPS, peek, etc

② Fiber type: glass fiber, carbon fiber, aramid fiber, basalt fiber and other high strength fibers

③ Thickness of products: 0.1-0.45mm

④ Product width: 150-1300mm

⑤ Product surface density: 100-650gsm

⑥ Fiber content of products: 40% - 70%

⑦ Traction speed: 5-25m / min

Ø Equipment description

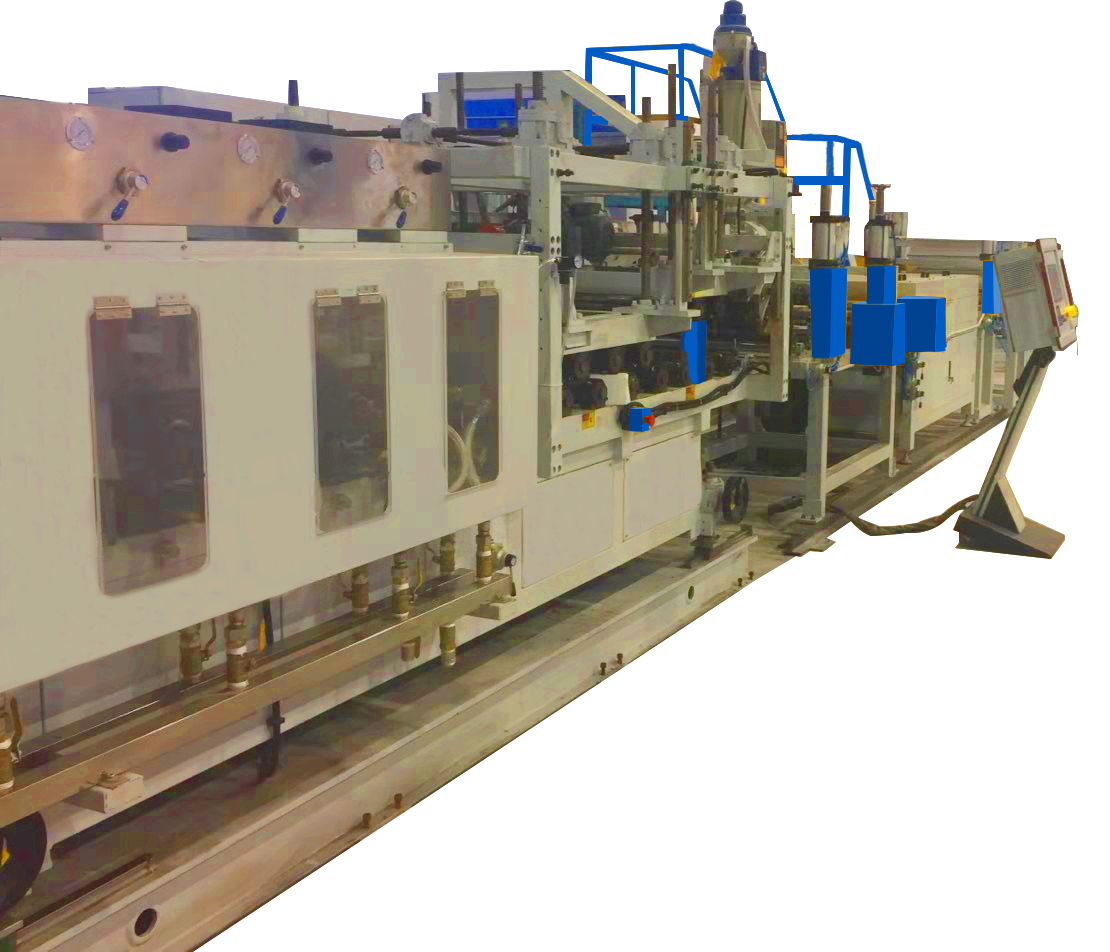

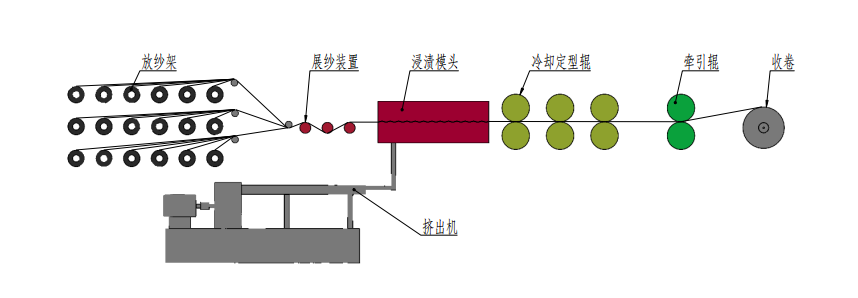

The unidirectional prepreg production line consists of yarn releasing device, yarn spreading device, melt impregnation device, hot pressing cooling device, traction device, winding device / or on-line film carrier device and automatic control system.

Ø Ø Characteristics of production line

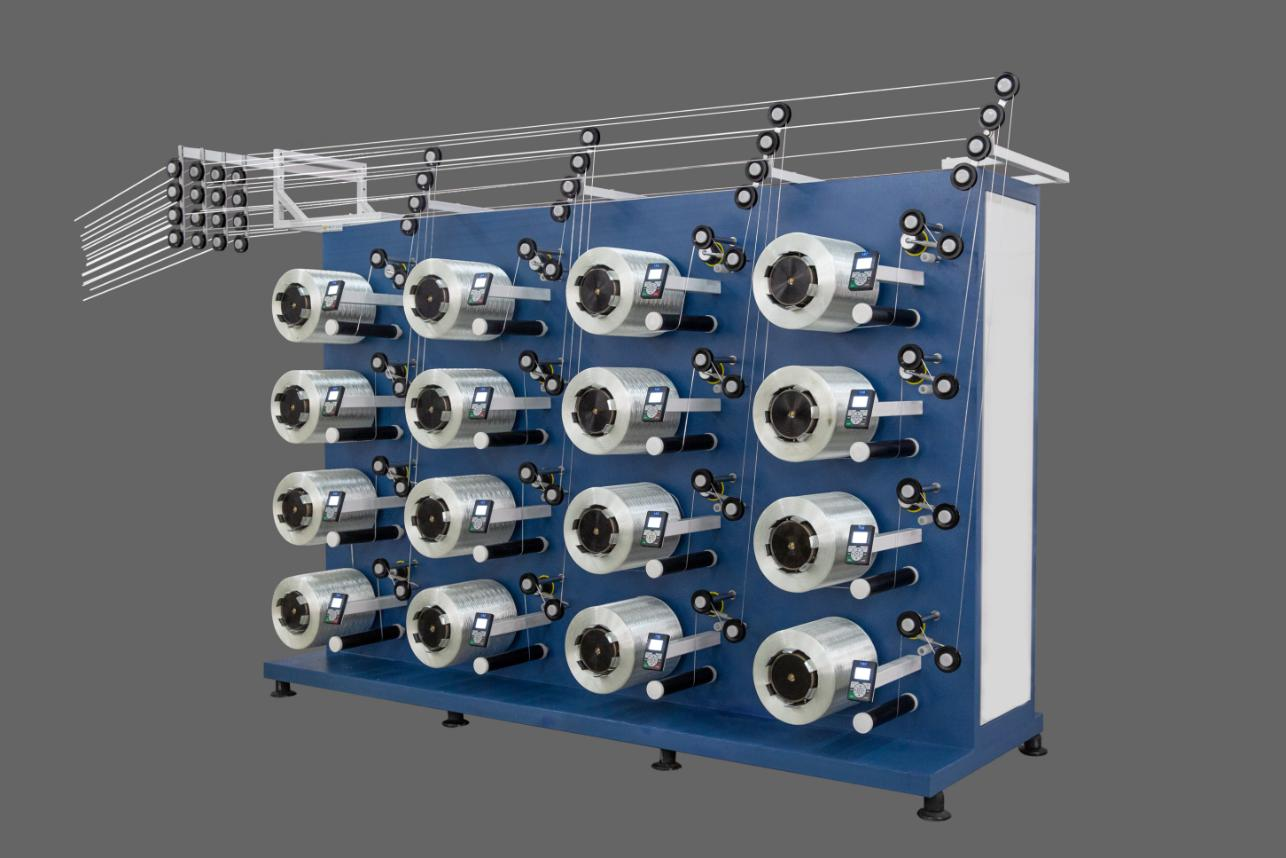

① Constant tension control, stepless adjustment, single roll, the whole can be adjusted

② There are many ways to unfold the yarn, such as roller system, vibrating system and air flow system

③ Proprietary impregnation mold technology (patented product), high function integration, online adjustable impregnation degree, reasonable structure

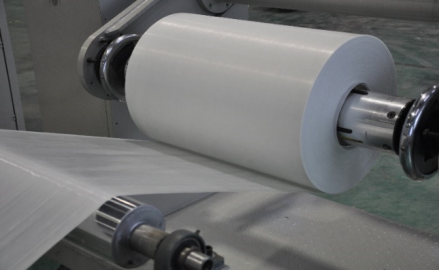

④ High precision cooling shaping control, more uniform product thickness

Ø Parameter table note: width can be customized according to customer requirements

|

Model |

BTD-150 |

BTD-330 |

BTD-650 |

BTD-1300 |

|

Effective width(mm) |

150 |

330 |

650 |

1300 |

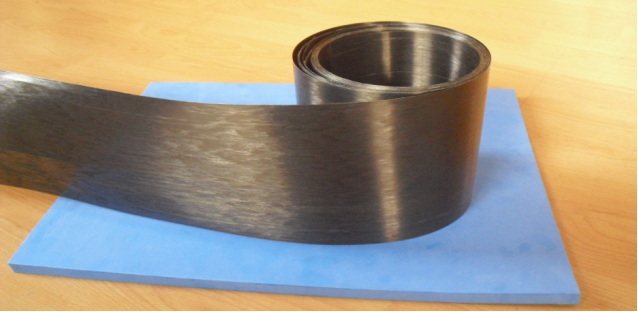

Glass fiber prepreg

Carbon fiber prepreg

Customer site equipment