- 1

- 2

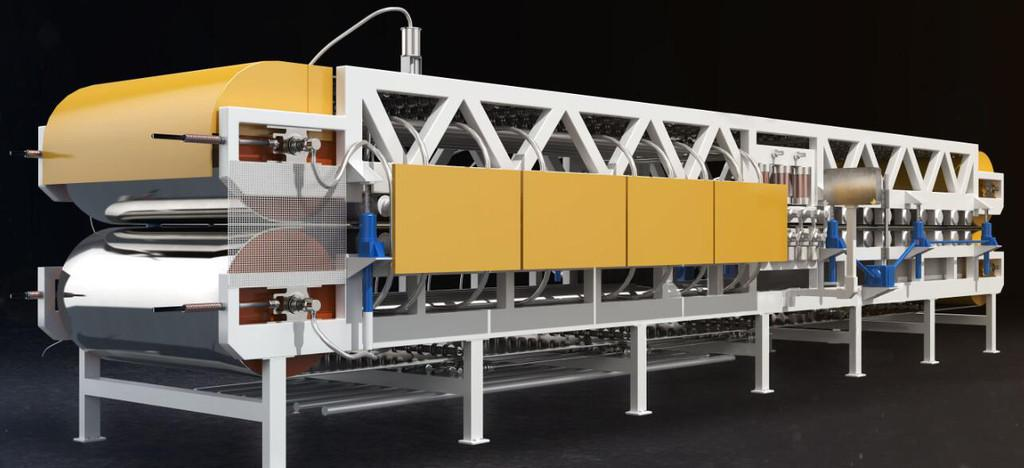

Continuous fiber reinforced thermoplastic composites equipment

(jointly developed with Beijing University of Chemical Technology) - continuous composite press production line

l Continuous compound press production line

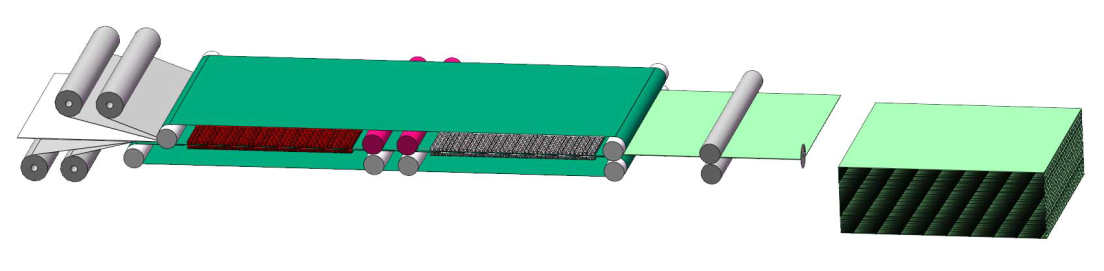

Flow chart:

Ø Equipment description

①It is divided into Teflon belt continuous compound press and double steel belt continuous compound press

②The continuous compound press production line is composed of unwinding device, compound host, traction device, winding device / or longitudinal cutting device, transverse cutting device, etc

③The composite host is composed of heating system, hot pressing system, cooling and curing system and automatic control system

²Heating system is divided into electric heating, oil heating and radiation heating according to different heating methods

²The hot pressing system is divided into counter roller module, circulating roller module and constant pressure module

²The cooling and solidification system is controlled by an independent cooling unit and optimized flow channel arrangement for accurate temperature control, and a special supercharging module is used for pressure control

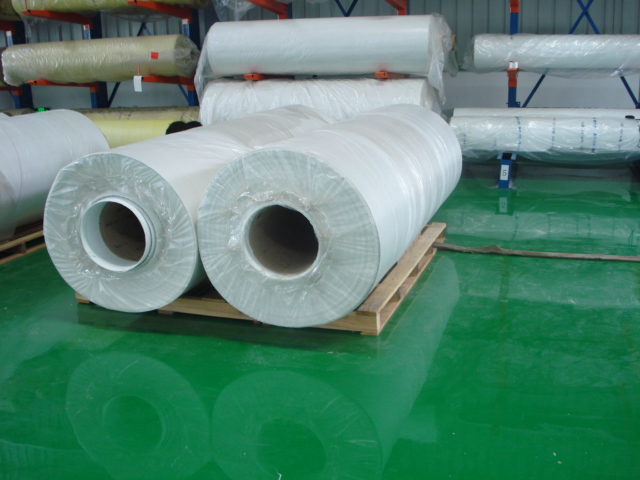

Composite products - formed coil

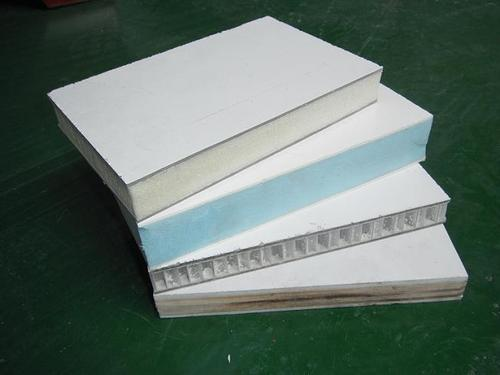

Composite products - formed sheet

Teflon belt compound press-1

Teflon belt compound press-2

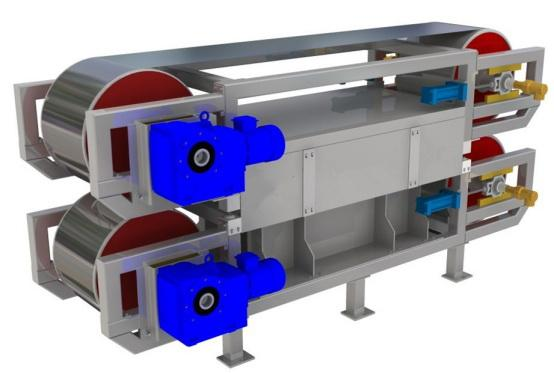

Double steel strip compound press-1

Double steel strip compound press-2

l Production line of Teflon belt continuous compound press

①Width of processed products:500~3200mm

②Thickness of processed products:~150mm

③Reference length of combined heating module:1.5m、2m

④Reference length of combined cooling module:1.5m、2m

⑤Hot pressing system of main engine: counter roller module, circulating rod module, equal pressure module

⑥Heating mode: electric heating, oil heating

⑦Process temperature:~250℃

⑧Running speed:0.5~10m/min

ØCharacteristics of production line

①Small equipment investment

②The main frame is processed as a whole and annealed with small deformation and high flatness

③Modular design

④Continuous production, high efficiency

ØParameter table: the width can be customized according to customers' requirements

|

Model

|

BTTY-500 |

BTTY-1000 |

BTTY-1500 |

BTTY-2000 |

BTTY-3000 |

|

Effective width(mm)

|

500 |

1000 |

1500 |

2000 |

3000 |

l Double steel strip continuous compound press production line

①Width of processed products:500~1500mm

② Thickness of processed products~150mm

③ Reference length of combined heating:1.5m、2m

④Reference length of combined cooling module:1.5m、2m

⑤Hot pressing system of main engine: counter roller module, circulating rod module, equal pressure module

⑥Heating mode: electric heating, oil heating, radiation heating

⑦Process temperature: ~ 450 ℃

⑧ Operating speed: 0.5 ~ 10m / min

ØCharacteristics of production line

①High production temperature, up to 450 ℃

②High flatness

③Modular design

④ Continuous production, high efficiency

⑤High pressure, the maximum line pressure of roller module can reach 80KN / m, and the maximum surface pressure can reach 5MPa

ØParameter table: the width can be customized according to customers' requirements

|

Modle |

BTTY-500 |

BTTY-1000 |

BTTY-1500 |

BTTY-2000 |

BTTY-3000 |

|

Effective width(mm) |

500 |

1000 |

1500 |

2000 |

3000 |